Setting up your warehouse properly will allow you to quickly reap the benefits of switching to Jazva. Our approach to warehouse preparation and inventory management is to minimize changes to the way you do business, while at the same time you take advantage of an inventory control system by transforming your current workflow into a streamlined, easy-to-scale warehouse operation.

We believe that a fast-growing ecommerce business can operate without need for expensive equipment such as picking robots or intricate conveyer belt systems. However, some less expensive equipment, such as barcode scanners and thermal printers, are an essential part of the Jazva experience.

Using barcode scanners drastically improves not only fulfillment and inventory handling speed, but also eliminates costly errors, so you can handle higher volumes accurately without the need for extra manual labor.

Thermal printers, located in the warehouse, enable real-time label printing, and even allow back-office personnel to print shipping labels and packing slips directly at the shipping station.

Chances are, your warehouses are already equipped to be able to use Jazva, and only minimal adjustments may be needed.

The main steps to prepare your warehouse include:

No inventory movement or rearrangement of the warehouse is required.

Here are a few "best practices" we would like to point out:

-

Have whole warehouse bin locations labeled, with proper labeling schema for ease of finding the bins

-

Do not try to store whole SKU at one location, same SKU can be stored at multiple locations. That avoids frequent need for moving items around

-

Store similar or similarly looking items (e.g. variations of same item) in different locations

-

Prioritize your bin locations so inventory is allocated to "best", easy to pick from locations

-

Train your personnel to have a strict discipline of not moving any inventory around, or picking/restocking without proper updates in the system. Ensure that ALL order sources, such as sales channels, manual order entry etc is properly recorded in jazva, so your jazva system updates inventory counts for every physical item picked

-

Implement process of receiving and put-away of inventory using jazva's receiving functionality

- Utilize barcode scanners (either with our web interface or mobile app)

- Perform partial stock counting on selected "problem" areas of the warehouse. You do not need to re-count the whole warehouse.

- Utilize Inventory -> Reconcile inventory page to see discrepancies between accounted for and officially recorded stock quantities

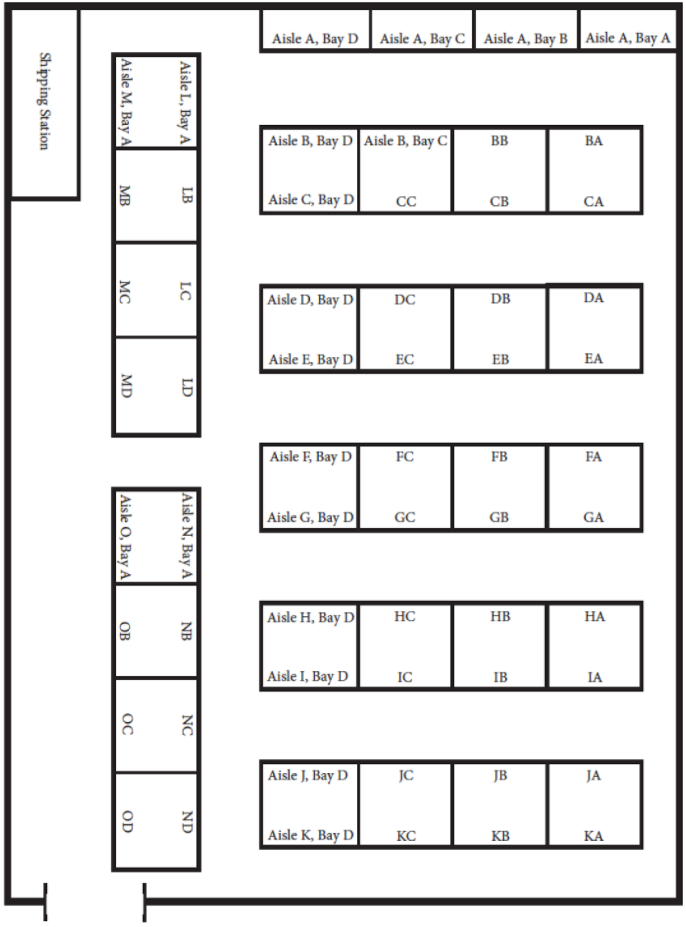

Sample warehouse layout

Comments

0 comments

Please sign in to leave a comment.