This document will help you prepare your warehouse for maximum efficiency as you transition into using Jazva.

Setting up your warehouse properly will allow you to quickly reap the benefits of switching to Jazva. Our approach to warehouse preparation and inventory management is to minimize changes to the way you do business, while at the same time you take advantage of an inventory control system by transforming your current workflow into a streamlined, easy-to-scale warehouse operation.

We believe that a fast-growing ecommerce business can operate without need for expensive equipment such as picking robots or intricate conveyer belt systems. However, some less expensive equipment, such as barcode scanners and thermal printers, are an essential part of the Jazva experience.

Using barcode scanners drastically improves not only fulfillment and inventory handling speed, but also eliminates costly errors, so you can handle higher volumes accurately without the need for extra manual labor.

Thermal printers, located in the warehouse, enable real-time label printing, and even allow back-office personnel to print shipping labels and packing slips directly at the shipping station.

Chances are, your warehouses are already equipped to be able to use Jazva, and only minimal adjustments may be needed.

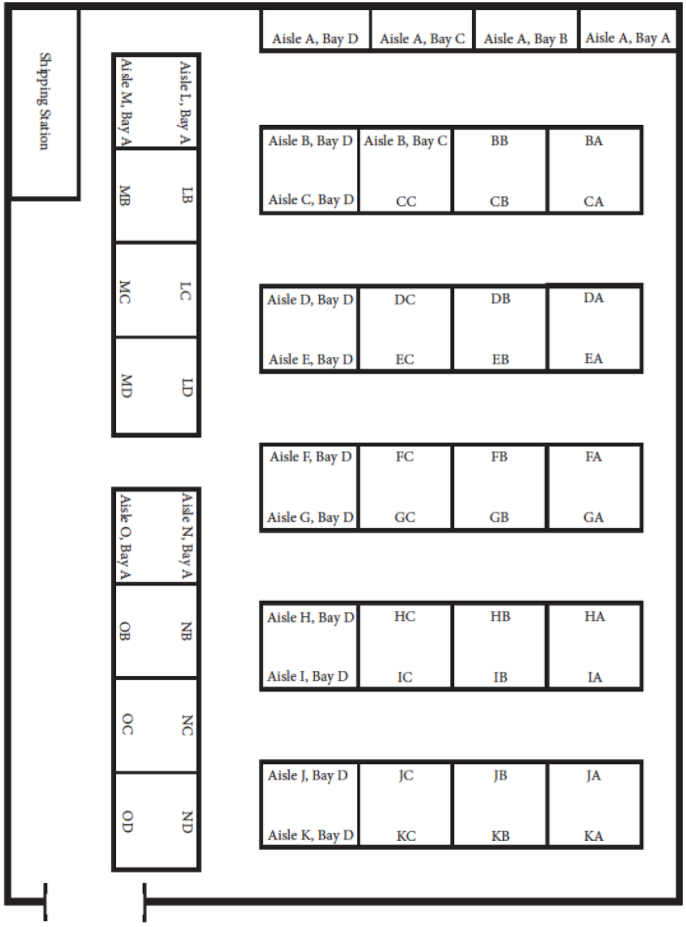

The main steps to prepare your warehouse include setting up shipping and receiving stations as well as labeling shelves with bin location labels printed by Jazva. No inventory movement or rearrangement of the warehouse is required.

Sample warehouse layout

Comments

0 comments

Article is closed for comments.